Mission Style Furniture: Understanding the Construction Methods Used by Stickley

Mar 20th 2023

Mission style furniture has been around since the 19th century and its name is derived from the Spanish missions in California, which were built in the early 18th century by Spanish colonizers. Stickley, a company founded in 1900 by Gustav Stickley, is one of the most well-known manufacturers of Mission style furniture. Stickley’s mission is to make high-quality furniture with durable, long-lasting construction using traditional techniques. Here, we’ll explore the construction methods used by Stickley furniture to give you a better understanding of what makes Mission style furniture so unique.

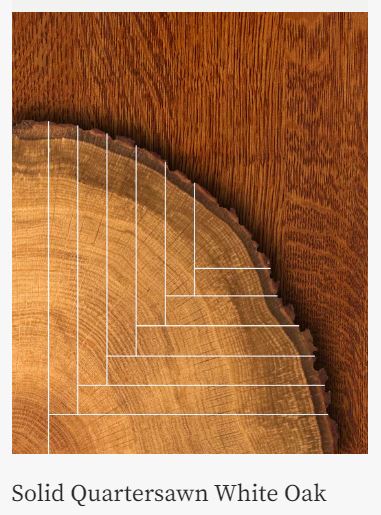

Using Solid Wood

One of the most important aspects of Mission style furniture is the use of solid wood. Stickley uses only high-quality hand-selected hardwoods, including Quartersawn White oak, cherry, walnut, and mahogany. They use solid wood for all parts of their furniture, including the frames, legs, and tabletops. Solid wood not only gives a beautiful and warm aesthetic, but it also provides durability and longevity.

Mortise and Tenon Joinery

The most common technique used in the construction of Stickley furniture is mortise and tenon joinery, which involves fitting two pieces of wood together in a way that creates a strong and stable joint. This technique is widely used in the construction of Mission style furniture because it is simple yet effective. Each joint is carefully cut by hand so that it fits together perfectly. This technique not only provides strong joint, but it also creates a beautiful, natural aesthetic.

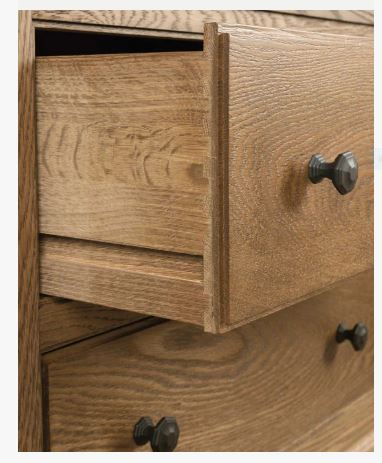

Side hung and center guided drawers

The center guide keeps drawers from skewing sideways. Side suspension keeps drawer level when heavily loaded. No plastic parts to break. No metal to rust and scratch, just honest to goodness hand craftsmanship. The drawer never scrapes the bottom and opens and closes with ease.

In the 1930's, Leopold Stickley designed this drawer guide system to eliminate the deterioration of the cross rail due to the friction of the drawer bottom scraping on it. Previous to the new guides system Stickley, and most manufacturers simply let the drawer drag on the cross rail. The result is clearly seen on many older chests and dressers. Two grooves have been scraped into the rails by the friction year after year.

Dovetail Joinery

Stickley also uses dovetail joinery, which adds stability and longevity to the construction of furniture. Dovetail joints are made by creating interlocking shapes in two different pieces of wood that fit perfectly thus creating a strong connection that is less likely to come apart over time.

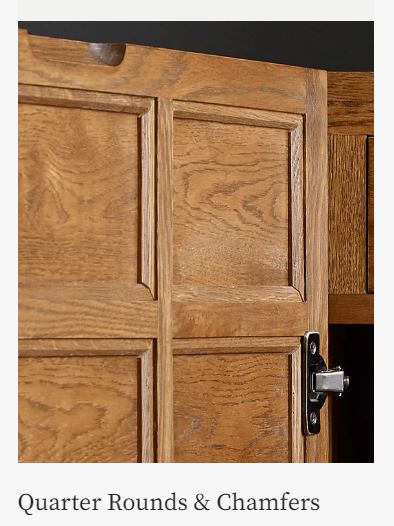

Quarter round

A quarter round is the smallmoldingsthat hold the panes of glass into place on Stickley China cabinets and bookcases. It is both sturdy and attractive. There are few manufacturers who take the time to make this joint. Most manufacturers use plastic to hold the glass in place.

Tongue and Groove glue joint

Instead of simply butting the edges of boards together to be glued, the boards receive a small groove on one edge and a small moulding (tongue) on the opposite edge. The tongue fits snugly into the groove giving the glued panel greater strength. Additionally, the glued-up boards will be set together more precisely resulting in a greater thickness dimension. Stickley is one of the only high-end furniture manufactures still taking the time to do this joint.

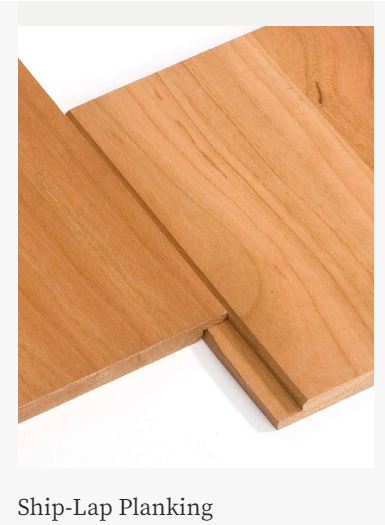

Shiplap Planking

Shiplap is a plank of solid wood which has a moulded edge. When the planks are laid side by side, one edge "laps" over the edge of the next. This allows for expansion and contraction. Ship lapping is done on many of the Stickley bookcases and China cabinets in place of plywood. Shiplap adds a slightly informal look to a design. That is why some of the Stickley formal cabinets have plywood backs. Plywood is uniform and does not have the vertical lines that could tend to clash with the intricate designs on the door front of a formal cabinet Shiplap adds more cost to any piece. That is why some of our lesser priced bookcases have plywood backs.

Pinned Mortis-and-Tennon Joinery

Most Stickley door joints are tenoned, glued, and pinned with wooden pins. The pins lock the joint, supplying additional strength. This joint would hold together even without the use of glue. Some styles are pinned from the front and are visible, others from the back.

Finishing Techniques

The finishing techniques used by Stickley make a big difference in the quality and appearance of the furniture. Stickley uses hand-rubbed finishes that are done in multiple steps to create a rich, deep color that brings out the natural beauty of the wood. This process is done entirely by hand, creating an individual, unique look.

Conclusion

Stickley has been the leading manufacturer of Mission styled furniture for over 120 years. They are known for their high-quality construction techniques and durable materials. When you buy Stickley furniture, you can be sure you are buying a piece that will last a lifetime. With solid wood, mortise and tenon joinery, dovetail joinery, and unique finishing techniques, Stickley creates furniture with a classic timeless look that will be cherished for generations to come.